Aluminum or aluminium is the second most-produced metal in the world. Everyone has at least a few items in their homes that contain aluminum. Appliances, cooking utensils, TVs, all have aluminum in themselves.

Since there are so many household items that are made from aluminum, it’s expected that something breaks or cracks. In those instances, it is important to use the proper tools to mend the damage effectively. The proper tool, in this case, would be glue or adhesive that will successfully bond aluminum.

You might be having a DIY project that involves some aluminum parts that need to be tied together. You will need an appropriate glue to do so depending on what kind of material you want to bond aluminum to.

So, we know that we need some kind of adhesive to adhere to aluminum parts. But what is the best glue for aluminum?

This is the question we will answer in this article. Read on to find all the information about the best aluminum adhesives on the market and a guide that will help you identify what kind of glue you need for your particular situation.

Last update on 2025-01-31 / Affiliate links / Images from Amazon Product Advertising API

What is the best glue for aluminum?

There is no easy answer to this question. It hugely depends on the type of aluminum in question and do you want to bond it to another aluminum part or a different material. There are also several other factors to consider, such as curing time, environmental factors, and temperature resistance.

There are 3 main types of adhesives that work best for aluminum bonding. Those are:

- Cyanoacrylates, or more commonly referred to as super glues

- Polyurethane Adhesives

- Epoxy Adhesives

We will now go deeper into each of these 3 adhesive options and see what they are best suited for.

Super Glues

Super glues are probably the most popular and user friendly glues today. They are extremely easy to use and are very inexpensive which makes them great for many small, everyday household fixes.

Super glues are also very well suited for metal bonding. They can not only bond aluminum but also other materials such as wood, plastic, or glass. They usually have a fast setting time and are easy to clean. There are many super glue options that are water or heat resistant which makes them very versatile.

While they are easy to use and very handy for small repairs, super glues have their limitations. They do provide strong bonds but are prone to breaking when they face resistance from various angles. That’s why it’s best to use an epoxy or polyurethane adhesives for bigger cracks and holes that require greater tensile strength.

Epoxy Adhesives

These adhesives are great for aluminum bonding. They have amazing strength and are well suited for filling holes and gaps. Epoxies are very durable and waterproof.

They can easily be coated or sanded after they’ve cured. Epoxies are also known for their ability to hold a bond when there is resistance from any kind of angle.

They are available in single component and two component options. Both of these are great for bonding aluminum. Single component doesn’t require mixing which is a great time saver but also requires heat to cure. Two component epoxy can cure at room temperature.

While epoxies are a great adhesive option for bonding aluminum they are not so easy to use. They require mixing adhesive and hardener, and many times they need a particular tool to be applied properly. Epoxies usually require clamping in order to bond properly.

Epoxies are very well suited for aluminum bonding, but if you don’t have much experience with adhesives, they might be troublesome to work with.

Polyurethane Adhesive

Polyurethane adhesives do an excellent job in bonding aluminum. They are one of the strongest adhesives out there and are classified as construction adhesives.

They do an excellent job of outdoor mending because of their great UV and water resistance. They have a great cold and hot temperature resistance as well.

Setting time for polyurethane adhesives is usually very quick. The structural strength of this adhesive is very high, it can withstand a massive amount of pressure. With this adhesive, you can bond many large areas that could be impossible to bond with epoxies or super glues.

Polyurethane adhesives are best for outdoor use, and if you have any aluminum parts that need to be repaired that are outside the house, this is the adhesive to go for.

Best Adhesives For Aluminum – Reviews

In this section, we will recommend in our opinion the best glues for aluminum currently on the market. You will find that all of the recommended adhesives below are suitable for bonding aluminum to wood, aluminum to plastic, and of course aluminum to aluminum.

Additionally, we have picked the best super glues, polyurethanes, and epoxies for aluminum so that there is just the right glue for everyone’s preference and circumstances.

Our Pick

J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy

When we are looking for a great glue for aluminum we are looking for the one that sets quickly, has great tensile strength, has great temperature and water resistance. This is the adhesive that has all those features.

It bonds exceptionally on a variety of surfaces, including wood, metal, plastic, fiberglass, concrete, and many more. Its strength is ensured with steel reinforcement. That makes this epoxy’s tensile strength 3127 PSI, which is more than enough for most household repairs.

Setting time is 6 minutes which is very fast. The epoxy should cure in around 4-6 hours which is amazing since most epoxies need at least 24 hours to cure!

What’s great about this epoxy is that it can be used in a variety of environments, and it’s not restricted to household use only. It is able to resist temperatures up to 230 Fahrenheit! This epoxy is water resistant as well and that makes it great for outdoor or bathroom use.

This is an excellent, versatile adhesive that will bond aluminum to anything you wish! It is certainly one of the best adhesives for aluminum and probably the best epoxy on the market. If you’re not sure which glue for aluminum to choose, go with this one. You can’t go wrong with it!

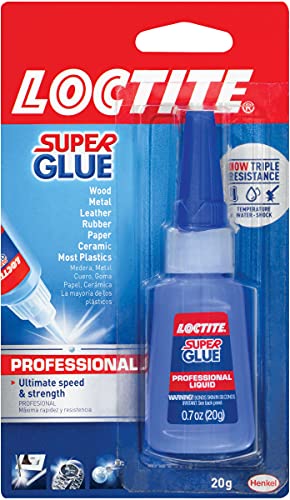

Best Super Glue For Aluminum

Loctite Professional Liquid Super Glue

If you don’t want to think long and do a ton of research but want to bond two or more pieces together, super glue is your best bet. It works on, well… everything!

While super glues are great for their versatility, there are some models that are better for certain applications. This Loctite professional super glue is phenomenal for bonding aluminum or any other metal.

It’s quite a lot stronger than standard super glue models and sets really fast. It needs just 15 to 30 seconds to set which is super fast! You can bond aluminum to not only other metals but to wood, plastic, and ceramics as well.

We like the specialized package of this super glue. It allows for a very precise application because of its narrow nozzle. This is really helpful for bonding small pieces together.

This is a great heavy-duty super glue that works brilliantly with aluminum. It’s so easy to use, just open the bottle and start working right away! If you just want to pick the glue for aluminum that works, choose this one.

Gorilla 7700104 Super Glue Gel

This is another great and versatile super glue for aluminum on our list. We just couldn’t write a list of adhesives without gorilla glue being in it. It’s a very reliable super glue that gets the work done.

This super glue gel does exactly what we want it to. It dries very fast in as little as 10 seconds! It’s incredibly strong for super glue and can glue aluminum to almost everything.

The container of this gorilla glue is very well designed. It’s made of sturdy plastic and will not break easily. This is an issue with many cheaper, no-name brands that tend to break and then dry out very quickly or even worse, leak the glue onto clothes and hands.

This gorilla glue is so versatile, even for super glue. Many customers have noted that they were able to bond their car parts together with this gorilla glue! Now, how amazing is that!

You won’t be let down by this gorilla glue. It’s one of the best glues for aluminum out there.

Best Epoxy For Aluminum

Gorilla 2 Part Epoxy

This gorilla epoxy is one of the best epoxies for aluminum we tried! The thing we like the most is this super cool syringe system. It’s so easy to use!

The Gorilla has made two separate barrels and syringes for hardener and resin. It’s such a simple system but it works great and helps you mix equal amounts of both components. Not to mention that it’s easier to handle and store one syringe than two!

This epoxy dries clear and looks very clean when cured. It makes a great epoxy for mending visible cracks or holes because of its clear looks.

The bond strength of this epoxy is 3300 PSI. It’s as strong as torch welding and will be sufficient for almost all household repairs.

It can be used on a lot of materials such as ceramics, plastic, wood and most importantly aluminum. You’ll have no problem bonding any material to aluminum with this heavy-duty epoxy.

Bob Smith Industries BSI-201 Quick-Cure Epoxy

Many people don’t like epoxies because of their curing time and that’s understandable. Not everybody wants to wait 24+ hours for a complete bond. If you are one of those people that appreciate the quick curing time, then this is the right choice for you.

With a curing time of just 1 hour, this Bob Smith Epoxy can be handled after only 15 minutes! That’s insanely quick for an epoxy. Some cheaper super glues have that kind of setting time.

Apart from the amazing drying time, this epoxy has a very solid tensile strength of 3500 PSI. That’s wonderful for such a low curing time. You will have no trouble adhering aluminum to all sorts of other metals and materials with this epoxy.

It comes in a two bottle packaging so mixing might be a bit of work but once you mix it, you will have a good 5 minutes to work with it before it starts to set.

It should also be noted that this epoxy is on the pricier side, but that is for a reason. It’s simply better than most of the cheaper alternatives and the quick curing time is absolutely worth it.

Best Polyurethane Adhesives For Aluminum

Loctite PL Premium Polyurethane Construction Adhesive

Need a super reliable adhesive that will stick no matter what? Go for polyurethane adhesive! Specifically, this Loctite 100% polyurethane construction adhesive will provide you with astonishing strength. It is as much as 3 times stronger than the regular construction adhesives! This toughness makes it perfect for heavy duty jobs such as sub flooring installations.

Apart from terrific sturdiness, you get a great temperature resistance. You will have no problem repairing something outdoors. The bond will stay strong through the freezing winter and steamy summer. This adhesive is waterproof as well, so you don’t have to worry about the bond through the wet season as well.

Setting time for this glue is around 60 minutes and it should cure in about 24 hours. It is recommended that you clamp the composite surface to ensure the strongest bond.

You can bond aluminum as easy as pie with this adhesive. It is compatible with so many other materials as well such as wood, stone, concrete, marble, brick, and many more. You can basically fix anything inside and outside the house with this wonderful adhesive.

It should be noted that this adhesive has a tan color when it sets. It is paintable though, so if the aesthetics are of importance this is a solution.

This adhesive comes with a bit of a price tag as well. But, it’s a heavy duty, professional quality adhesive, and you get 4 ounces of it. You will have no trouble fixing a lot of things before you run out of it. And there is always something to fix, so we feel that the price is very well justified.

Dap 18816 Polyurethane Construction Adhesive and Sealant

This reliable polyurethane adhesive from Dap is known for its strength and endurance. The Dap company is so confident in their product that they give you a 50-year durability guarantee!

This is the adhesive for heavy duty repairs such as boats, asphalt, flooring, and such. This adhesive is so robust that it can withstand heavy vehicle traffic.

You will have around 30 minutes of work time before this adhesive sets. Full strength or curing is attained in 4 to 7 days.

This polyurethane adhesive is very well suited for aluminum use. Specifically, it works great on windows, doors, and roofing aluminum parts. It will withstand all the environmental factors including rain, snow, and sun.

To further prove its underwater ability, this adhesive was used for many boat repairs, and all the customers were satisfied and had no complications even after a few years!

This is without a doubt a professional grade adhesive. We wholeheartedly recommend it for any type of work, inside or outside. It will provide long lasting bonds that you can rely on.

What to Look For When Choosing Adhesive For Aluminum

Strength, curing and setting time, Environmental factors ( inside-outside, water, humidity, hot, cold), Difficulty.

In this section, we will lay out important factors to consider when you’re choosing glue for aluminum. With this little guide, you will be able to pick the right glue for your circumstances and needs.

Strength

The strength or sturdiness of the adhesive you use on aluminum is very important. Not all repairs require a professional grade construction adhesive.

If you just need to bond two small aluminum pieces for your bike, you probably won’t need anything more than super glue. Anything stronger would be an overkill and a huge waste of time and money.

On the other hand, if you need to fix your aluminum roofing or some car parts, then you need to go for an adhesive with more structural strength. A lot of epoxies are well suited for these kinds of repairs. They usually have well over 3000 PSI of tensile strength.

If you have some heavy duty aluminum parts then polyurethane based adhesives will do the trick. Especially if the parts are located outside.

So, use super glues for simple household fixes, epoxies for more advanced repairs, and polyurethane adhesives for tricky outdoor mends that require sturdiness and endurance.

Setting And Curing Time

Fast or slow setting time, what is better? Well, it depends.

We recommend going for fast setting adhesives when you’re fixing smaller parts. You usually don’t need a lot of time to bond these parts correctly, and you don’t want to waste a lot of time by waiting for 30 minutes for an epoxy to set when you can just wait 15 seconds when using super glue.

Fast setting adhesives are also recommended if you have a bit more experience with repairs. If you’re not too confident or not skillful enough you might want to go for a slower setting glue for some extra time.

Like we previously mentioned, slow setting adhesives are good for beginners. They allow enough time for modification of the composite surface. And if you’re working on a more delicate repair, it helps to have some extra time if you notice you screwed up.

Slow setting adhesives are usually sturdier and require a proper bond. You always want to have a slow setting time when you’re working on a heavy duty mend.

Environmental factors

Environmental factors are a crucial element to consider when choosing an adhesive for aluminum.

For example, if you work in a low humidity environment you will most likely experience a much faster setting time than usually expected. In those instances, you will be better off opting for a slower setting glue for aluminum.

If the humidity is high and the temperature is low, you always want to go for a faster setting adhesive since the bond can take days instead of hours to set in that kind of climate.

If you’re fixing something outside, the adhesive used must be waterproof. Choose the one with great temperature resistance if you live in a particularly hot or cold area. Polyurethanes are great for all types of outdoor fixes. They can resist all environmental factors and are probably the best adhesives for outdoor use.

Difficulty

Often overlooked, the difficulty of handling, mixing, and applying a glue should also be considered.

Epoxies will always be harder to work with than super glues. If they are two component epoxies they have to be mixed properly in equal amounts of both hardener and resin.

On the other hand, super glue is so stupidly simple to use. Just unscrew the bottle and start gluing right away!

If the adhesive is heavy duty or professional grade, protective measures are also required. You should wear gloves to avoid the glue sticking to your hands since it’s much harder to get off than weaker glues.

How To Bond Aluminum With Glue

Here is a how-to bond aluminum part of this article. We will give you instructions on how to effectively bond aluminum to any other material. Let’s start.

First things first, we have to prepare the aluminum surface that we want to adhere to. Most surfaces of aluminum parts have something called an oxide layer. This is a thin layer that is not visible to the naked eye.

If you were to glue another part to the aluminum part without treating the surface, you would most likely end up bonding the other part to the oxide layer instead of the aluminum. We don’t want that.

The surface of the aluminum should not be just wiped but also roughened with sandblasting or similar procedures.

Here is the step by step list on how to prepare the aluminum surface for adhesion:

- Wipe the aluminum surface area with a solvent like Acetone.

- Roughen the area with sandpaper or similar tools.

- Wipe the aluminum surface one more time after roughening.

The third step is taken to ensure that the area is free from any dirt or debris and is ready for bonding.

Next, is the gluing part. The application of the adhesive depends on what type of glue you choose (super glue, epoxy, or polyurethane).

If it’s a super glue:

- Squeeze one drop per square inch of the composite surface.

- Bond the parts together.

- Clean any excess glue away as it can affect the final strength of the bond.

- After about 10 minutes the bond will reach full strength, it will cure in around 24 hours.

If it’s an epoxy putty:

- Cut the needed amount of putty.

- Work it with wet hands until it becomes constant in color.

- Force the putty into the gaps, holes, or cracks that need to be mended.

- Clean all the excess epoxy as it can affect the strength of the bond.

- It will set in up to 15 minutes, and after around 2 hours it will cure.

If it’s a two-component epoxy adhesive:

- Pour equal amounts of hardener and resin into a disposable container

- Mix them and apply to the parts within 5 minutes

- Clean any excess epoxy

- Clamp the parts, and leave them undisturbed for at least 24 hours

If it’s a polyurethane adhesive:

- Dampen the surface lightly with clean water before applying the adhesive

- Apply small amounts of the adhesive to the surface as it expands up to 3 times

- Remove any excess adhesive

- Clamp the parts and leave for at least 60 minutes

- Wait for at least 24 hours until the adhesive cures

Make sure to wait for a substantial amount of time before you try to use or put back the bonded part again. It’s wise to wait a bit longer than what the curing time manufacturer has stated since these low setting and curing times aren’t always 100% accurate.

Safety Recommendations

Before gluing or cleaning anything we need to first ensure that our work will be safe from any unwanted situations.

Wear Gloves and Protective Eye Goggles

We can’t stress this enough. The gloves will protect your skin from fast setting glues that can fix very quickly on your hands. Removing the dry glue from your hands can be a very frustrating and tedious task, so make sure to spare yourself of all the trouble and wear some gloves.

Protective Eye Goggles will protect your eyes from the glue. You might be wondering, how can you get glue in your eyes. Well, it’s easier than you think.

In a loss of focus, you might forget that the glue has smeared all over your fingers. You can then subconsciously touch your face around the eye area, perhaps if it’s itching. That’s why we recommend that you wear both gloves and protective goggles to ensure you are safe from any accidents.

Work in a Ventilated Area

Glues contain many dangerous chemicals such as ethanol and xylene. You definitely don’t want to work with those kinds of poisonous substances in a small room with no windows and air circulation.

If you can go for a room that has great ventilation and lots of fresh air coming in and out. If that’s not possible, another solution might be to work outdoors.

Read The Instructions

Manufacturer instructions are there for a reason. Most of the people are oblivious to the fact that many accidents wouldn’t happen if the people read the instructions in the first place.

Make sure to thoroughly read the parts where the safety measures are mentioned. Read the application parts to properly handle the adhesion.

Close The Lid Properly

After use, make sure to close the lid tightly to avoid any air getting inside the tube or glue spilling out. If you fail to do so, the glue will dry out and become unusable.

Work In Clothes That You Don’t Mind Getting Stained

Clothes that are old or torn are great for these kinds of situations. The stains from the strong adhesives are almost impossible to remove from clothing. So, don’t wear any regular clothes and save yourself from having to throw away good clothes.

Conclusion

That ends our quest for the best glue for aluminum. Like we mentioned, there are many features to consider. However, the most important thing is to choose the right glue for your personal situation.

You never want to cheap out when you’re repairing heavy duty parts, but you also don’t want to spend your time and money on an overkill adhesive that wasn’t necessary.

We hope that our guide has improved your knowledge and that our recommended products made your decision easier.